Helium, which is to be liquefied at low temperatures, has to meet very high purity requirements. Impurities arise during experimentation (contamination: air), during storage (contamination: air and moisture) and when compressing with high pressure compressors (contamination: oil)

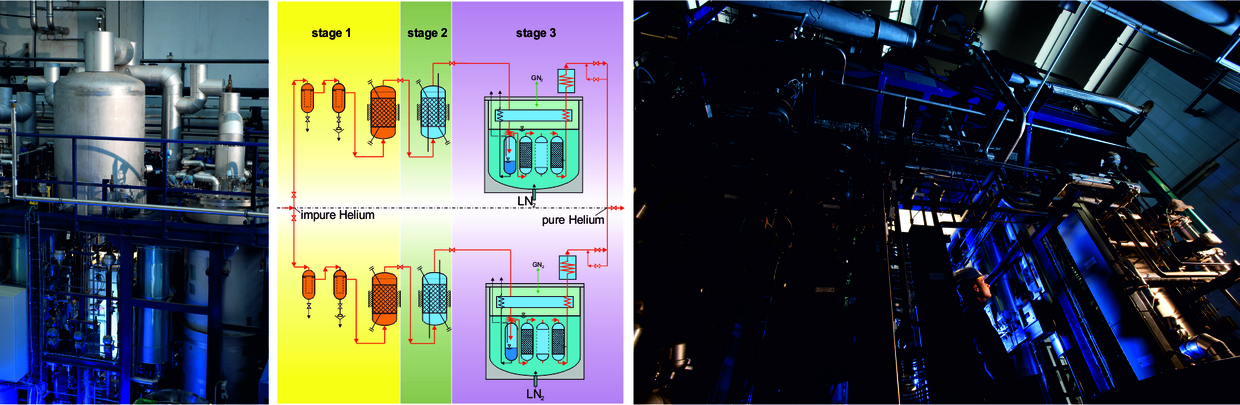

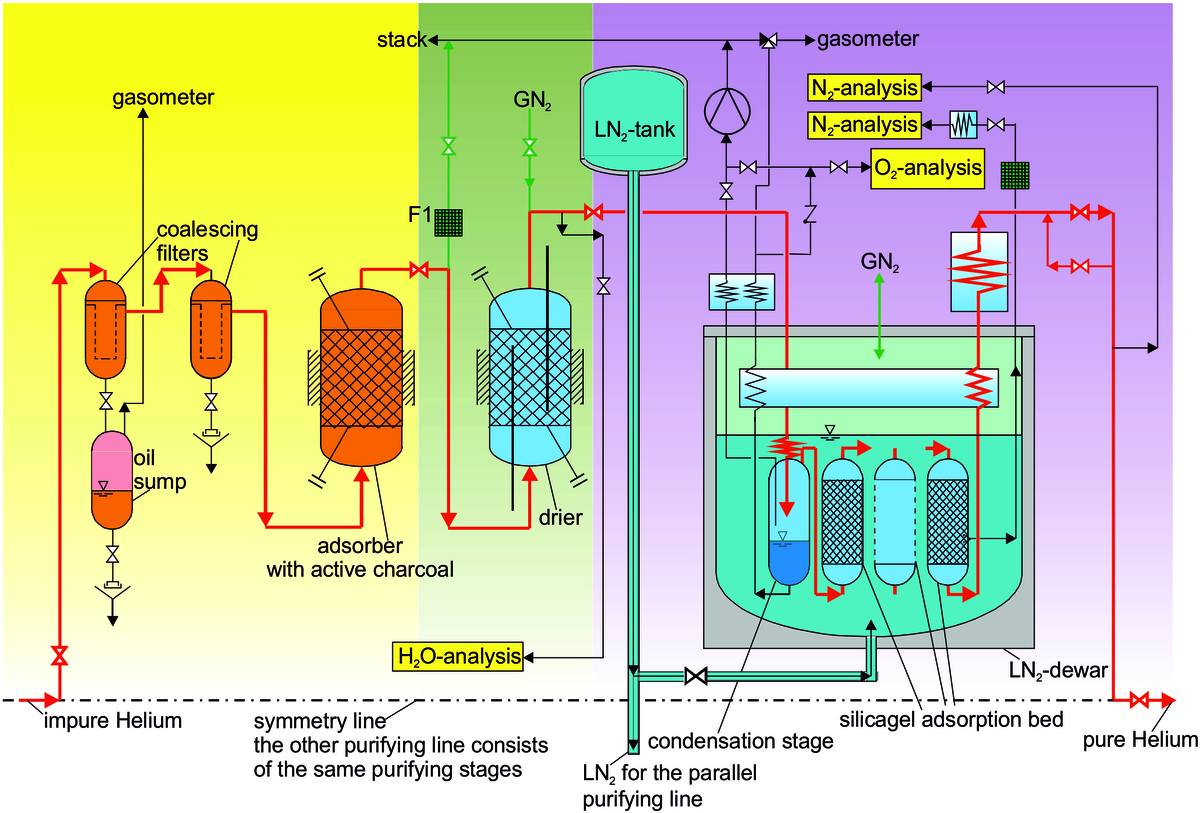

The Helium purification system removes the impurities in three stages

-

STAGE 1 - A coalescer removes oil droplets an a subsequent activated carbon adsorber adsorbs oil vapors.

-

STAGE 2 - A molecular sieve adsorber dries the helium and adsorbs CO2

-

STAGE 3 - A silica gel adsorber that is cooled to 77.4K adsorbs nitrogen and oxygen.

The He purification system achieves a degree of purity of 99.9999%, i.e. for every 1 million parts of helium there is 1 part of impurities (= 1 parts per million = 1ppm).

The purification system consists of two parallel cleaning columns, one of which cleans and one regenerates.

Technical details:

Manufacturer - Air Liquide

Throughput - maximum 28g / s at 200bar

Cleaning capacity

- Oil contamination - 10mg / Nm³

- Humidity - saturated φ = 1

- Air pollution - maximum 3% (briefly 10%)

Product quality - Helium 6.0 (<1ppm impurities)