Wire and Cable Technologies

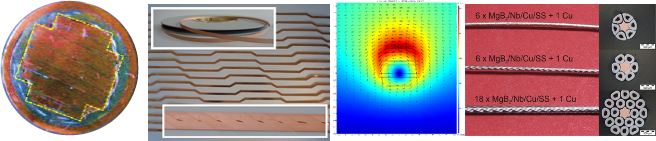

Superconducting applications in magnet and power engineering require cost-effective high-current carrying superconductor wires on a km scale, which are adapted and optimized to the respective application scenarios in their various properties (e.g. mechanical strength, magnetic field compatibility, alternating current losses, ...). In the field of classical low-temperature superconductors for applications in medicine and research, NbTi or Nb3Sn wires have become established, depending on the required magnetic field compatibility. These wires are manufactured using classical metal forming technologies to form multifilament conductors. Current research is focused on the further development of Nb3Sn PIT (Powder-In-Tube) manufacturing technologies for accelerator magnet applications. High-temperature superconductors (HTSC) for magnet and power engineering applications are used in the form of coated tape conductors. In particular, a solution-based chemical coating technology allows the cost-effective production of high-current carrying tape conductors. For alternating current and high current applications, specially structured tape conductors and cables consisting of several individual conductors are required. At the ITEP, several research groups are intensively researching conductor and cable technologies in order to make promising superconductor materials usable for convincing applications of superconductivity in magnetic and power engineering.