Rotating Machines

In the research topic Rotating Machines, we develop and test superconducting electrical windings for use in rotors and stators of various applications. Selected applications are wind power generators (AC or DC design), turbo generators, and motors & generators for electric flying.

Particular emphasis of the research is in the following areas:

Superconducting rotors: The high current densities allow the construction of very compact rotors with high magnetic fields in the air gap. Machine specifications, material limitations and cooling require specific expertise. For example, electric strength and variation of excitation require a special insulation technique for the windings.

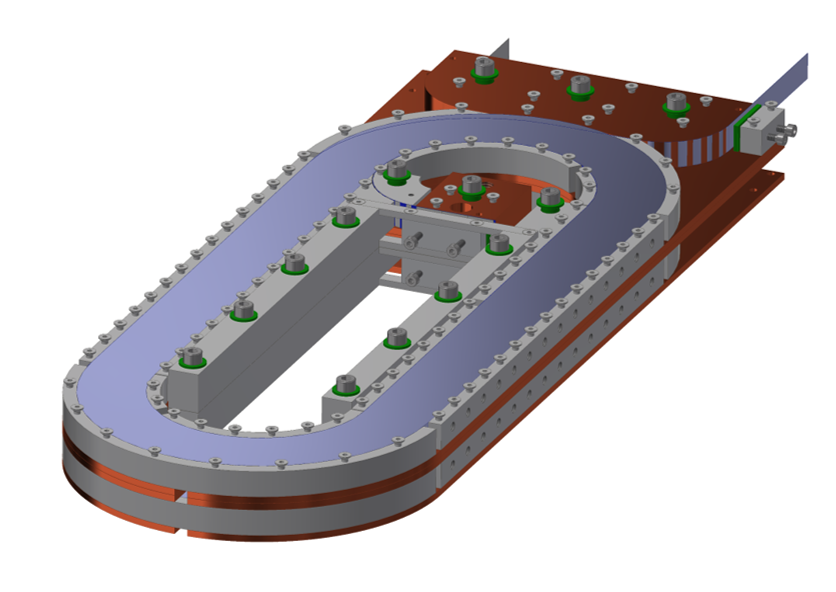

Superconducting stators: Superconductors in stators are a challenge for superconductors. Depending on the electrical frequency, considerable AC losses occur. The winding system must be optimized accordingly. In most cases, complex geometries, which go beyond simple solenoids, pancake or racetrack coils, and possibly have dedicated end windings, have to be investigated and developed for this purpose.

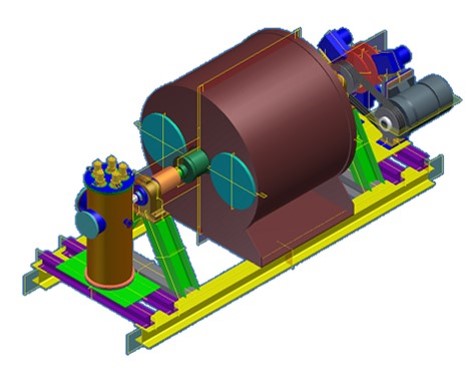

Heat dissipation under rotation: The wide spread applications cover a large range of rotational speeds (from about 10 rpm to 3600 rpm). Different cooling concepts can be advantageous for the different speed ranges (cold gas cooling, heat conduction, heat-pipes, combinations thereof, ...). The cooling concepts must be reliable under operating conditions with regard to cooling capacity and the integrity of the overall system. For this purpose, a "test-rig" will be erected offering the options for research, characterization and qualification of large (turbo) rotors under operating conditions in a spin bunker (proof-of-concept).