Vacuum technology and cryovacuum technology

As part of the development of new systems and technologies for the fuel cycle of a fusion power plant, we are working on the so-called metal foil pump (MFP) as well as diffusion and ring pumps. The MFP has the task of separating the majority of the unused hydrogen (deuterium and tritium) in the reactor's exhaust gas flow in order to feed it back directly as fuel. This is aimed at drastically reducing the tritium inventory of the entire plant and significantly smaller gas processing plants in the vicinity of the reactor. The MFP itself is based on the principle of superpermeation, a process that only allows hydrogen isotopes to pass through a metal foil after additional energetic excitation in a cold plasma. As this process, in contrast to conventional permeation, also works at low pressures, even against a pressure gradient, this separation unit is called a hydrogen metal foil pump.

The additional vacuum pumps required downstream of the separation stage of the MFP are diffusion pumps and mechanical backing pumps. The challenge here is to develop tritium-compatible pumps. For this purpose, a linear diffusion pump and a liquid ring pump were designed, which were further developed for operation with mercury as the working fluid. This was necessary because the usual operating fluids oil and water would quickly become tritiated in the reactor.

All these developments are permanently based on simulations of the reactor behavior with regard to the pumpability of different divertor designs of the machine, the flow conditions to and in the separation and pumping units as well as the expected mixtures and impurities that have to be handled. This interaction between prediction, design, optimization and adapted, targeted technology development is our path to comprehensive solutions for the fusion power plant.

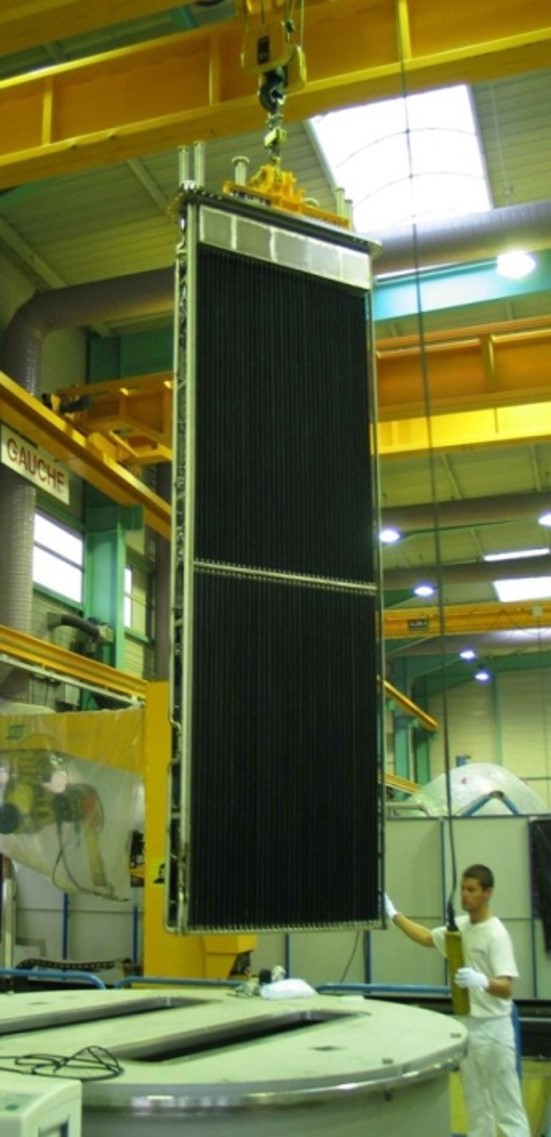

Our commitment to vacuum solutions in fusion started over 20 years ago with the development of customized cryogenic pumps for various applications in ITER and many other fusion facilities. Cryopumps pump gases by adsorption on cold surfaces. This expertise is still available and, although probably no longer relevant for the future of fusion, we will continue to maintain and contribute it. We are currently supporting the development of the Einstein Telescope, the planned third-generation European gravitational wave observatory currently under development. Here we are simulating the extreme vacuum requirements and implementing the results in a cryopump concept for the entire interferometer, which allows us to make statements about the required cryogenic infrastructure even at this early stage.

Our expertise

- Development of the so-called metal foil pump, the heart of the DIR concept for tritium inventory reduction of a fusion fuel cycle

- Development of tritium-compatible vacuum pumps with mercury as the working medium

- Development of customized cryogenic pumps with any pumping speed

- Simulations of diluted gas flows, development of corresponding codes

- Design of all types of vacuum systems (from microreactors to particle accelerators)

- Construction and operation of test facilities

Long-term projects

- Development of cryogenic and non-cryogenic vacuum pumps for nuclear fusion

- Development of cryogenic pumps for the Einstein telescope

- Investigation and development of very large NEG pumps as a replacement for cryogenic pumps

Research infrastructure:

- HERMESloom and HERMEStecc facilities for investigating superpermeation at low pressure and under external magnetic field

or to support the development of metal foil pumps