Project objective

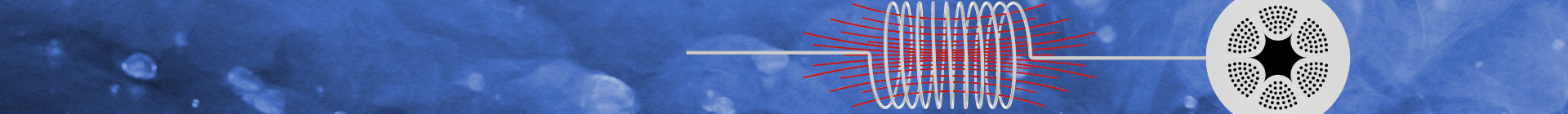

Development of a high-temperature superconducting high-current busbar for continuous use in an aluminum plant.

The aim of this project is to reduce the voltage drop from approx. 12 V to a range of less than 0.5 V by using superconductors instead of the two 600 m long aluminum return lines. This would result in energy savings of around 90 % and a CO2 reduction of 10,000 t/a. The aim of the project is to realize these loss savings by operating the superconducting 200 kA busbar. This is to be developed, constructed and operated within the project.

ITEP's task is to provide scientific advice and evaluate the data. The ITEP will not incur any hardware costs.

- First continuous operation of a superconducting high-current busbar in industry.