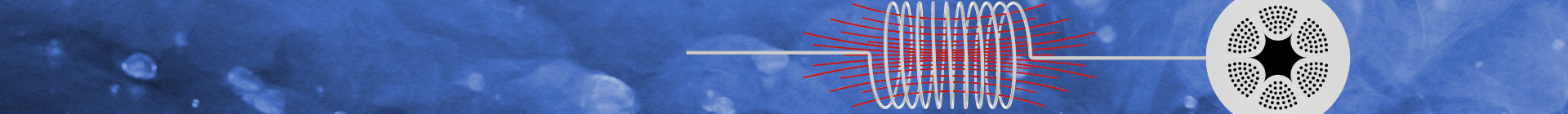

conductor concept of HTS CroCo

In reality, the easiest way to fill a circular cross-section is by using a stack of suitably fitting REBCO tapes (left diagram). This was suggested in 2005. However, a continuous twisting of such a unit during the production was only possible if a torsion force was applied during production and continuing it along the production and then transferring it again and again in the same way - this type of production is technologically inefficient.

The torsion is much easier if the superconductor cross-section is designed in the form of a cross. On the one hand, the circular cross-section is closely maintained and thus at a good superconductor filling level, and on the other, the torsion can be applied with a form fit using a suitable tool (shown here in blue in the middle diagram). The advantage here is that the superconductor core to be produced can simply slip through, while absorbing the necessary force for twisting.

Hereby the HTS CrossConductor (HTS CroCo) takes shape, which can still be completed by a surrounding round tube (shown dashed in the right hand diagram).

Scientific publications on the conductor concept of the HTS CroCo:

- M. J. Wolf et al., HTS CroCo: A Stacked HTS Conductor Optimized for High Currents and Long-Length Production, DOI: https://doi.org/10.1109/TASC.2016.2521323